Aluminium casting repair

Client: Local Transport Company

Project description:

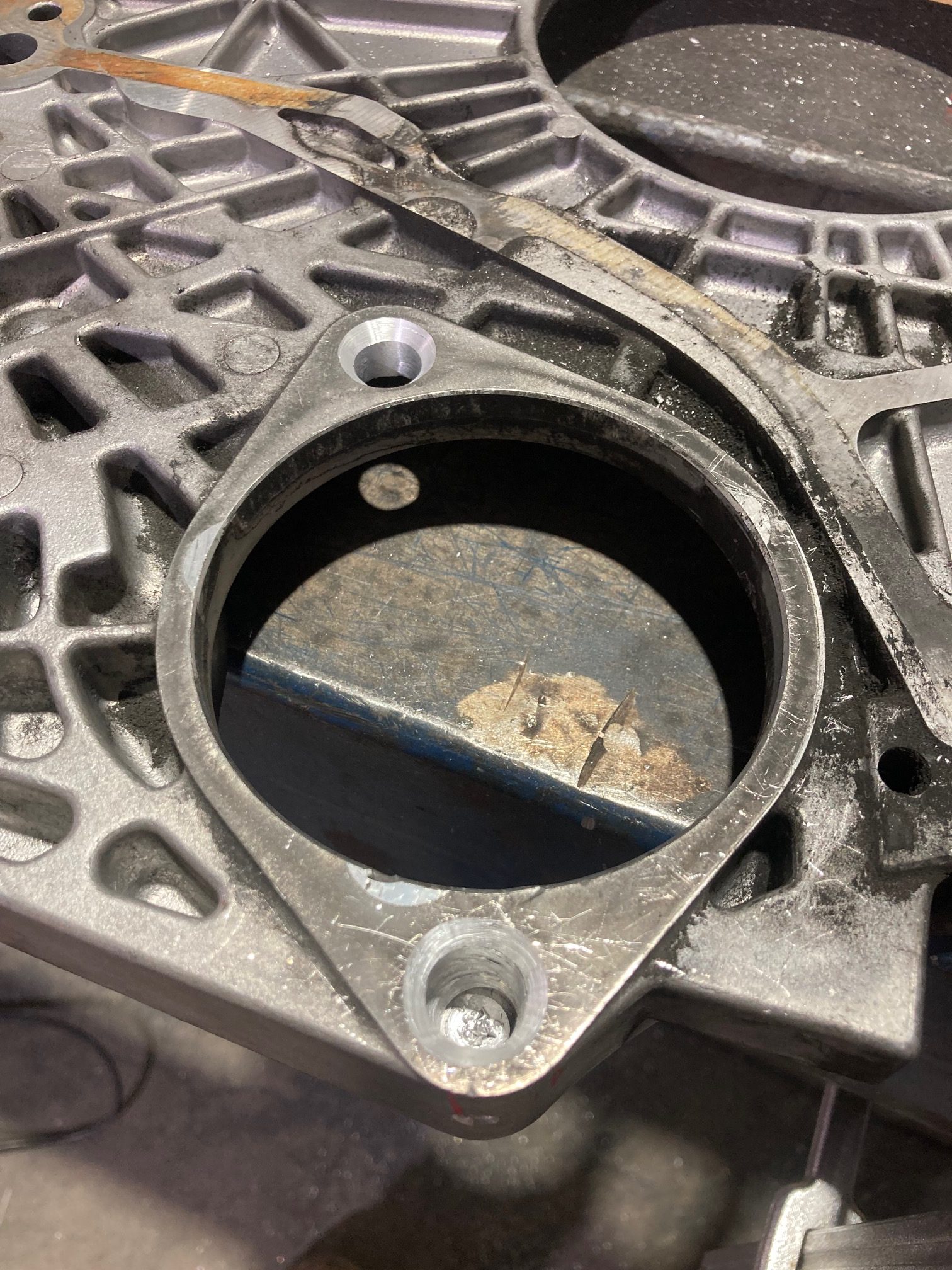

Aluminium casting repair.

A local transport company required the services of a Brisbane welder and fabricator with specialisation in aluminium welding to repair an aluminium casting.

The project required repair of damaged threaded holes in an aluminium forklift bell housing.

What were the challenges?

One of the holes was “blind” meaning it did not go all the way through the casting.

This meant the side of the hole had to be cut away to allow access so the hole could be filled with weld from the bottom all the way to the top.

How did Davis Welding and Fabrication solve these challenges?

Carefully the side of the hole was removed and using a TIG welder the holes were filled and filed flat.

The original hole locations were marked from a template taken prior. The holes were drilled and tapped to the appropriate thread.

Project result

The aluminium welding repair was successfully completed and the client could get their forklift running again quickly to minimise down time.

Category:

Date:

December 16, 2023